| Material 材质 |

| 铜+冷却液 copper+cooling liquid |

| Catalog N o. | L | ||||||||

| Type | D | 40-80 | 81-120 | 121-150 | 151-185 | 186-220 | 221-250 | 251-275 | 276-300 |

| JH075 | 3 | 390 | 390 | 490 | 490 | 610 | 610 | 680 | 730 |

| 4 | 340 | 340 | 410 | 410 | 490 | 490 | 540 | 610 | |

| 5 | 340 | 340 | 410 | 410 | 490 | 490 | 540 | 610 | |

| 6 | 340 | 340 | 410 | 410 | 490 | 490 | 540 | 610 | |

| 8 | 440 | 440 | 540 | 540 | 680 | 680 | 730 | 850 | |

1成形循环可缩短30%以上(高速吸热与冷却)

2.可获得残留应力少的成形品(防止产品缩水与变形)

3.成形品精度佳(冷却水不沸腾)

4.成形品外表面佳(防止水垢产生)

5.可减少颜色不均的现象(可长时间运转)

6.模具保养很有效,因此可维持精度,并减少劳动力。

7.只需装上附加的热管, 即能进行模具改良。

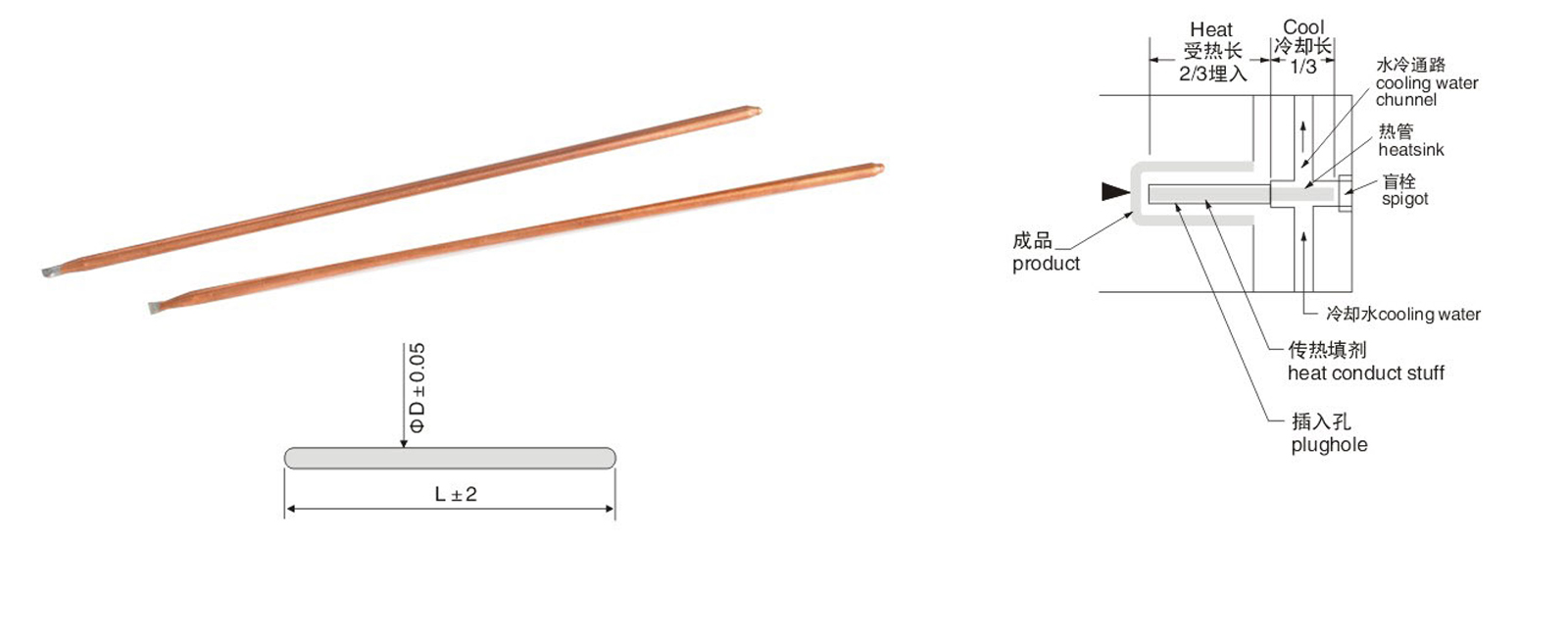

安装方法:

1安装冷却管的孔径加工要比冷却管大0.1m/m-0.2m/m.

2冷却管装入后,请用传热填剂将多的空间填满。

3冷却水道孔径加工请比冷却管大两倍以上。

4冷却管安装时,请将冷却管总长的1/3或2/3长度埋入模具之内以确保安全。

1.Can save at least 30% of molding cycle(super absorbency and cool down time) .

2.Less cull in molding products.(can prevent the final products from shrinkage and deformation)

3.Produce highly accurate final molding products(Preventing water from boiling)

4.0utstanding surface on the final products(avoid any water waste)

5.Can prevent color from inconsistency.(endure long-hour operating time)

6.Helps maintaining molds and reducing labor cost.

7.Simply add heatsink to improve molds function.

Installation:

1.When installing into molds ,please make sure the space is at least 0.1mm to 0.2mm wider than heatsink.

2. After installing,please use fitters to fill the gap.

3.Leave at least twice of the hole space for water cooling path.

4.For safety please insert at least 1/3 of heatsink into molds.

订购:222-冷却棒(热管) JH075